Ultrasonic Sensors vs. Optical Sensors

Accurate sensing is critical to maintaining efficiency, quality, and safety. Whether your machine needs to see with light or sense with sound, we’ve got the tools to make your automation smarter, sharper, and more reliable. di-soric offers a wide range of Ultrasonic and Optical Sensors designed to meet the demanding needs of modern manufacturing. So which is better for your application?

Dependable in Challenging Conditions

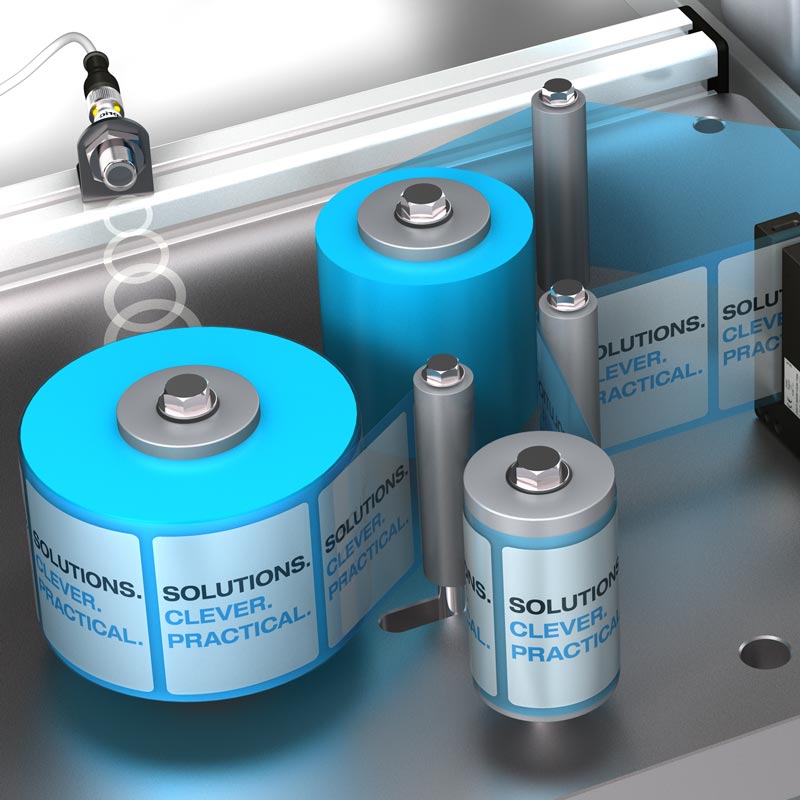

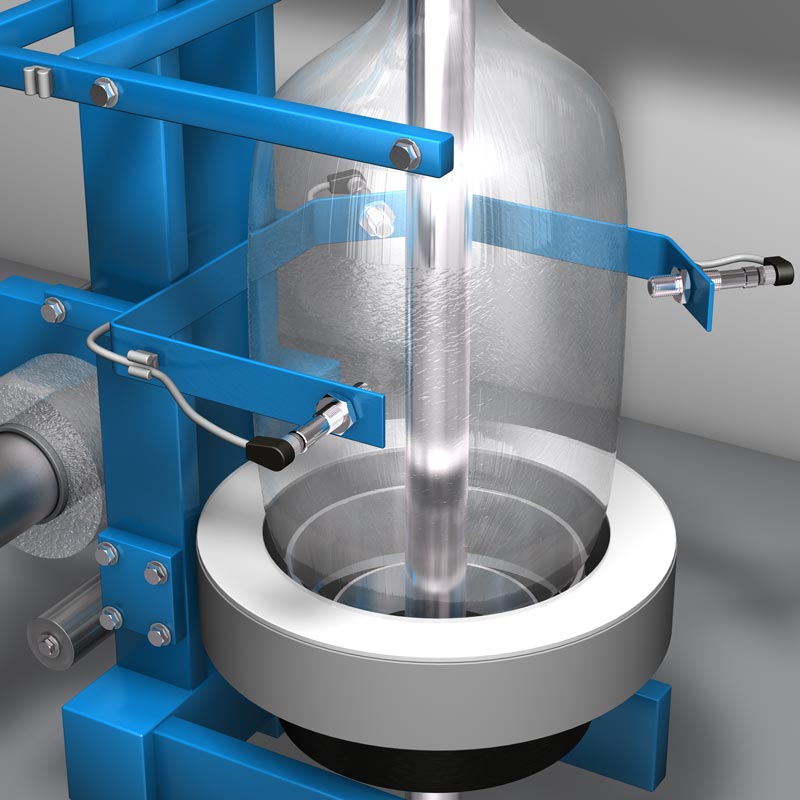

Ultrasonic sensors emit sound waves (ultrasound) and measure the time it takes to reflect back (echo) di-soric Ultrasonic Sensors are engineered to operate in environments where optical sensors may struggle, such as areas with dust, steam, or transparent materials.

Key Advantages:

- Reliable detection of objects regardless of color, surface, or transparency

- Excellent performance in dusty, humid, or poorly lit environments

- Ideal for fill level monitoring, presence detection, and material handling

- Compact designs for flexible installation

- Ideal for challenging industrial environments.

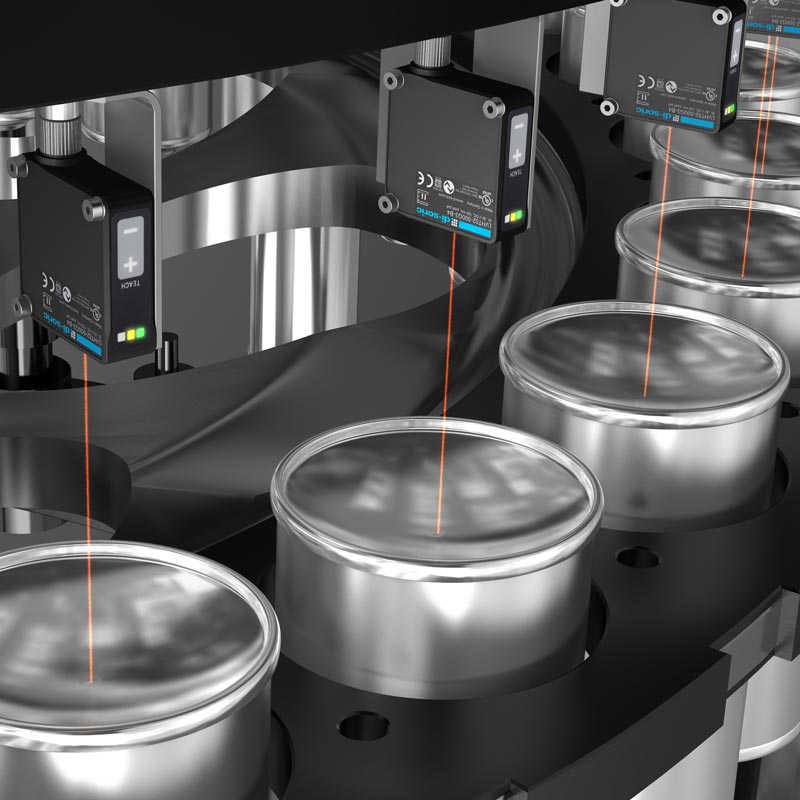

A High-Speed, High-Precision Solution

Optical sensors use light (laser or LED) to detect reflected signals or beam interruption. di-soric optical sensors offer precise detection and measurement for high-speed, high-accuracy applications. With laser-based models and advanced background suppression, these sensors support exact positioning and quality control in clean environments.

Key Advantages:

- High-resolution measurement for precision applications

- Fast response time for dynamic production lines

- Reliable detection of small parts or edge positions

- Robust construction and easy alignment

- Ideal for precision applications in clean, dry, and well-lit settings.

Common Applications for Distance Sensors

Fill Level Detection

- Measure the height of individual items or stacked materials

- Works well even when objects have similar surfaces or colors

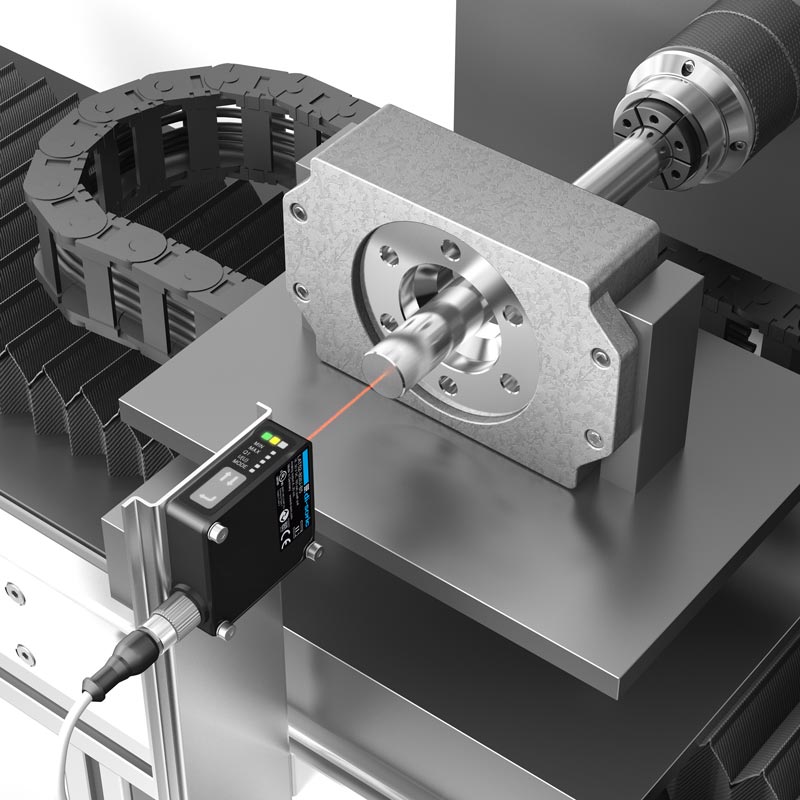

Distance Measurement

- Detect how far an object is from the sensor to control or adjust processes

- Track objects moving toward or away from the sensor (along the detection axis)

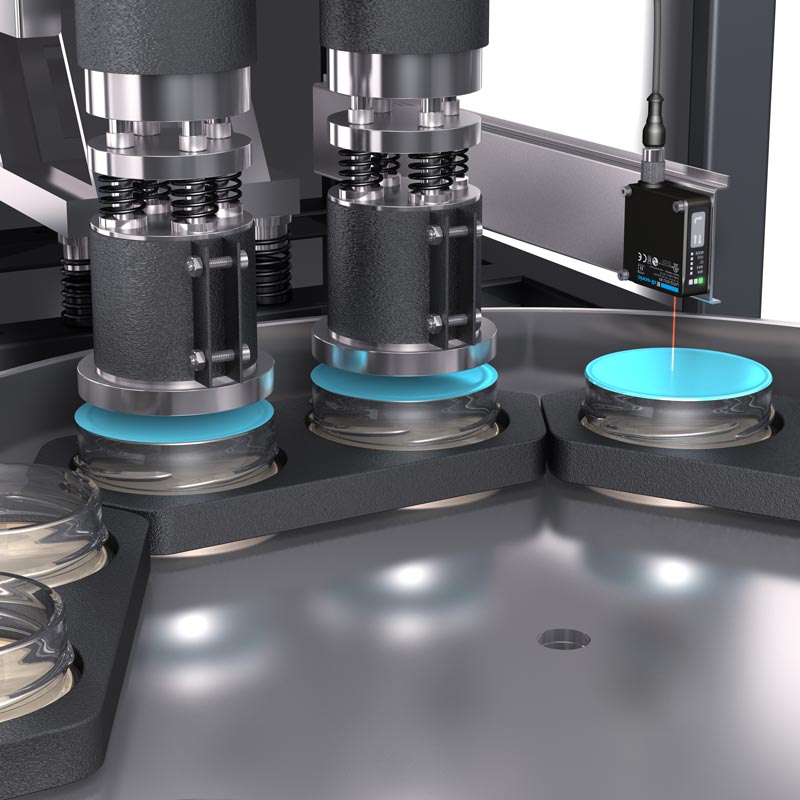

Positioning

- Precisely position objects with similar shapes or properties

- Monitor movement along the sensor’s detection axis

Quality Control

- Check whether an object is present or missing

- Verify that objects are in the correct location

Diameter Measurement

- Measure the diameter of objects to support production control

- Effective even when object size, shape, or material varies

Thickness Measurement

- Measure the thickness of moving objects, even at high speeds

- Ideal for movement across the sensor’s detection axis

Profile & Contour Detection

- Capture the shape or contour of moving parts

- Designed for objects moving across the sensor’s detection axis

IO-Link Integration – Smarter Sensing

Both di-soric’s ultrasonic and optical sensors are available with IO-Link, allowing seamless integration into Industry 4.0 environments. IO-Link enables advanced diagnostics, remote configuration, and real-time data monitoring to improve operational visibility and reduce downtime.

Specialized Optical Sensor Options

di-soric offers Fork Light Barriers and Cubicle Sensors that both deliver reliable, non-contact detection in compact, rugged designs, supporting faster, smarter automation with minimal maintenance.

When to Use Cubicle Sensors

- Enabling compact sensing in space-constrained environments

- Allowing flexible mounting in control cabinets or machine frames

- Supporting general-purpose object detection at short ranges

- Delivering cost-effective sensing for standard automation tasks

Take Advantage of Ultrasonic & Optical Sensors in These Industries:

Assembly & Handling Technology

Packaging

Robotics

Laboratory Automation

Mobile Equipment

Rubber & Plastics

Machine Tools

Ready to discuss how the di-soric ultrasonic and optical Sensors can improve your automated assembly and packaging processes?

Fill out the form below to schedule a call with our experts. If you need immediate assistance, give us a call at 332-282-2855.